Wire Bar Coaters OR Impression Beds

Product Details:

- Frequency 50 Hz

- Capacity Standard and custom capacities available

- Temperature Range Ambient to 50C

- Feature Uniform film thickness, easy cleaning

- Power Source Manual

- Core Components Wire bar, bed plate, adjustable mechanism

- Accuracy 1 m

- Click to view more

Wire Bar Coaters OR Impression Beds Price And Quantity

- 1 Piece

- 5000 INR

- Up to 400 mm

- Highly polished stainless steel bed

- Up to 300 mm

- Compatible with most standard substrate materials

- Micrometric screw for precise gap setting

- Used for making consistent film coatings for laboratory samples, inks, paints, adhesives, and coatings.

- Detachable, easy to clean construction

Wire Bar Coaters OR Impression Beds Product Specifications

- Manual

- Wire Bar Coater / Impression Bed

- Uniform film thickness, easy cleaning

- Stainless steel, anodized aluminum

- Manual mechanical

- Precision coating applications, lab testing

- Ambient to 50C

- Standard and custom capacities available

- 450 x 250 x 140 mm (approx.)

- 50 Hz

- Manual

- 1 m

- Wire bar, bed plate, adjustable mechanism

- Up to 400 mm

- Highly polished stainless steel bed

- Up to 300 mm

- Compatible with most standard substrate materials

- Micrometric screw for precise gap setting

- Used for making consistent film coatings for laboratory samples, inks, paints, adhesives, and coatings.

- Detachable, easy to clean construction

Wire Bar Coaters OR Impression Beds Trade Information

- 5-10 Piece piece Per Month

- 6-8 Week

Product Description

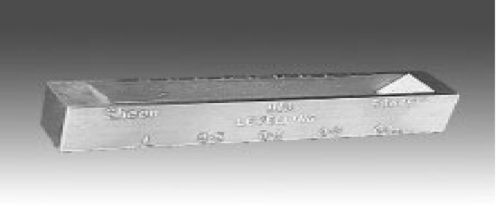

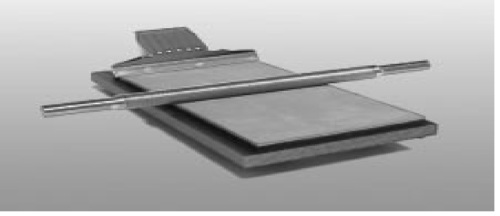

Wire Bar Coaters OR Impression Beds

These bars are ideal for the application of inks and coatings onto flexible materials such as paper, card, textiles, leather etc.

The coating thickness applied is controlled by the area of the groove between the coils of wire. As the material levels a smooth uniform thickness is produced. Impression beds hold the substrate material firmly in place to ensure accurate drawdown.

| SKU | Name | |

|---|---|---|

1120/18/10 | Wire Bar Coater 18cm film width, 10um Wet Film | |

1120/18/16 | Wire Bar Coater 18cm film width, 16um Wet Film | |

1120/18/26 | Wire Bar Coater 18cm film width, 26um Wet Film | |

1120/18/36 | Wire Bar Coater 18cm film width, 36um Wet Film | |

1120/18/50 | Wire Bar Coater 18cm film width, 50um Wet Film | |

1120/18/76 | Wire Bar Coater 18cm film width, 76um Wet Film | |

1120/18/100 | Wire Bar Coater 18cm film width, 100um Wet Film | |

1120/18/128 | Wire Bar Coater 18cm film width, 128um Wet Film | |

1120/18/150 | Wire Bar Coater 18cm film width, 150um Wet Film | |

1120/18/200 | Wire Bar Coater 18cm film width, 200um Wet Film | |

1120/18/A | Wire Bar Coater 18cm film width, Special sizes | |

1120/18/IMP | Small impression bed - Bed size 11 x 18cm. | |

1120/25/10 | Wire Bar Coater 25cm film width, 10um Wet Film | |

1120/25/16 | Wire Bar Coater 25cm film width, 16um Wet Film | |

1120/25/26 | Wire Bar Coater 25cm film width, 26um Wet Film | |

1120/25/36 | Wire Bar Coater 25cm film width, 36um Wet Film | |

1120/25/50 | Wire Bar Coater 25cm film width, 50um Wet Film | |

1120/25/76 | Wire Bar Coater 25cm film width, 76um Wet Film | |

1120/25/100 | Wire Bar Coater 25cm film width, 100um Wet Film | |

1120/25/A | Wire Bar Coater 25cm film width, Special sizes | |

1120/25/IMP | Large impression bed - Bed size 22 x 34cm. | |

1140/32/10 | Wire Bar Coater 32cm film width, 10um Wet Film | |

1140/32/16 | Wire Bar Coater 32cm film width, 16um Wet Film | |

1140/32/26 | Wire Bar Coater 32cm film width, 26um Wet Film | |

1140/32/36 | Wire Bar Coater 32cm film width, 36um Wet Film | |

1140/32/50 | Wire Bar Coater 32cm film width, 50um Wet Film | |

1140/32/76 | Wire Bar Coater 32cm film width, 76um Wet Film | |

1140/32/100 | Wire Bar Coater 32cm film width, 100um Wet Film | |

1140/32/128 | Wire Bar Coater 32cm film width, 128um Wet Film | |

1140/32/150 | Wire Bar Coater 32cm film width, 150um Wet Film | |

1140/32/200 | Wire Bar Coater 32cm film width, 200um Wet Film | |

1140/32/A | Wire Bar Coater 32cm film width, Special sizes |

Engineered for Uniform Coatings

Our Wire Bar Coater / Impression Bed utilizes carefully constructed core components, including a stainless steel bed plate and adjustable wire bar, to deliver uniform film thickness every time. The precision micrometric adjustment enables accurate settings, meeting the stringent requirements of laboratory testing and research.

Designed with User Convenience in Mind

Cleaning and maintenance are hassle-free, thanks to the detachable parts constructed from stainless steel and anodized aluminum. The mechanical display and manual operation ensure reliability, while the device remains compatible with most standard substrate materials used in scientific studies.

FAQs of Wire Bar Coaters OR Impression Beds:

Q: How does the Wire Bar Coater ensure uniform film thickness during application?

A: Uniform film thickness is achieved through the combination of a highly polished stainless steel bed and a micrometric screw mechanism, which allows precise adjustment of the gap between the wire bar and the substrate. This ensures consistent coatings in laboratory applications.Q: What types of materials can be coated using this equipment?

A: The coater is compatible with most standard substrate materials, making it suitable for applying coatings on laboratory samples, including inks, paints, adhesives, and other surface finishes.Q: When should I clean the Wire Bar Coater, and how is it cleaned?

A: Cleaning is recommended immediately after each use to prevent residue buildup. The design allows for quick detachment of components, making the process simple and efficient using standard laboratory cleaning solutions.Q: Where can this device be used most effectively?

A: This equipment is most effective in laboratory environments requiring precision coatings, such as research facilities, quality control labs, and development centers for paint, ink, and adhesive industries.Q: What is the process of adjusting the coating thickness?

A: The coating thickness is adjusted using the micrometric screw mechanism, which alters the gap between the wire bar and the substrate. This manual adjustment provides high accuracy, up to 1 m.Q: What are the benefits of using a manual Wire Bar Coater over automated systems?

A: Manual operation offers greater control over the coating process, making it easier to tailor thickness and coverage for specific research needs. It also reduces maintenance complexity and cost compared to automated alternatives.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese Get A Quote

Get A Quote