Four Sided Applicator

5000 INR/Piece

Product Details:

- Measurement Range 5~150 microns (depending on model)

- Capacity 4 different thicknesses (e.g., 5, 10, 15, 20 microns)

- Automation Grade Manual

- Temperature Range Ambient

- Feature Four precision edges with different gaps

- Power Source Not required (manual)

- Core Components Applicator blade, labeled thickness sides

- Click to view more

X

Four Sided Applicator Price And Quantity

- 1 Piece

- 5000 INR/Piece

- Polished

- Easy to clean, corrosion resistant

- Glass, paper, metal plates, test cards, and more

- Straight, each edge precision ground

Four Sided Applicator Product Specifications

- Uniform film application for coatings, paints, inks, etc.

- Within 1 micron (depends on model)

- 80 x 40 x 40 mm (approx.)

- Varies as per thickness set

- Manual operation

- Stainless Steel

- Not required (manual)

- Applicator blade, labeled thickness sides

- Ambient

- Four precision edges with different gaps

- Four Sided Film Applicator

- 4 different thicknesses (e.g., 5, 10, 15, 20 microns)

- Manual

- 5~150 microns (depending on model)

- Polished

- Easy to clean, corrosion resistant

- Glass, paper, metal plates, test cards, and more

- Straight, each edge precision ground

Four Sided Applicator Trade Information

- 5-10 Piece Per Month

- 6-8 Week

Product Description

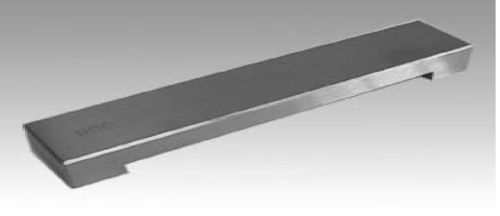

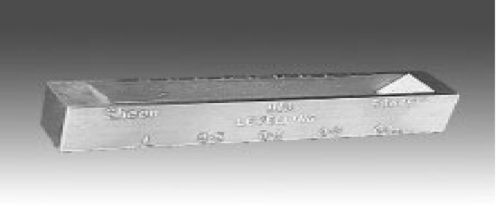

Discover the acclaimed Four Sided Applicatoran unmatchable tool for uniform film application. Magnificently engineered from polished stainless steel, it features four precisely ground straight edges, each offering a scarce, precisely labeled thickness (e.g., 5, 10, 15, 20 microns). Its transcendent accuracy, within 1 micron, makes it indispensable for coatings, paints, inks, and more on glass, paper, and metals. With supply ending soon, secure this manual, corrosion-resistant applicator and join leading exporters, importers, manufacturers, and traders across India.

Distinct Features and Versatile Applications

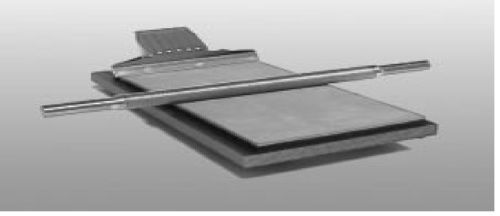

The Four Sided Applicator boasts a polished surface and robust stainless steel construction, ensuring durability and easy cleaning. It is designed for precise coating thickness control on glass, paper, metal plates, and test cards. Each straight edge delivers a different, clearly marked micron gap, allowing users to create uniform films for testing paints, inks, and coatings. Its manual operation and multipurpose usage make it ideal for laboratories, manufacturing, and research environments.

Supply Ability, Packaging & Dispatch Policy

We maintain consistent exchange and supply of Four Sided Applicators with a focus on quick dispatch and secure packaging. Each applicator is boxed with protective layers to prevent transit damage. Our sample policy is customer-centric, providing samples upon request to ensure satisfaction before final transaction. Timely delivery is our standard, and bulk or custom orders receive prioritized handling to meet project timelines efficiently.

Distinct Features and Versatile Applications

The Four Sided Applicator boasts a polished surface and robust stainless steel construction, ensuring durability and easy cleaning. It is designed for precise coating thickness control on glass, paper, metal plates, and test cards. Each straight edge delivers a different, clearly marked micron gap, allowing users to create uniform films for testing paints, inks, and coatings. Its manual operation and multipurpose usage make it ideal for laboratories, manufacturing, and research environments.

Supply Ability, Packaging & Dispatch Policy

We maintain consistent exchange and supply of Four Sided Applicators with a focus on quick dispatch and secure packaging. Each applicator is boxed with protective layers to prevent transit damage. Our sample policy is customer-centric, providing samples upon request to ensure satisfaction before final transaction. Timely delivery is our standard, and bulk or custom orders receive prioritized handling to meet project timelines efficiently.

FAQs of Four Sided Applicator:

Q: How does the Four Sided Applicator ensure uniform film application?

A: The applicator features four precision-ground straight edges, each with a distinctly labeled thickness, allowing for highly consistent and uniform application of coatings, paints, and inks on various substrates.Q: What surfaces can I use the Four Sided Applicator on?

A: This tool is suitable for glass, paper, metal plates, test cards, and other flat substrates commonly used in laboratory and industrial testing.Q: Where is the Four Sided Applicator commonly used?

A: It finds regular application in laboratories, quality control departments, research centers, and manufacturing facilities dealing with paints, coatings, and ink films.Q: What is the process for cleaning the applicator?

A: The polished stainless steel construction offers easy cleaning and excellent corrosion resistance; simply wipe with a non-abrasive cloth and appropriate cleaning solution after use.Q: When can I expect delivery after placing my order?

A: We offer quick dispatch and efficient delivery services. Orders are typically processed immediately after confirmation, with expected arrival times communicated at the time of exchange.Q: What are the benefits of using this Four Sided Applicator?

A: Key benefits include precise control over film thickness, robust build quality, corrosion resistance, and versatility across various film application tasks.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese Get A Quote

Get A Quote