Sag Index Applicators

Product Details:

- Power Source Manual

- Capacity Multiple gap heights for creating precise sag index patterns

- Automation Grade Manual

- Voltage Not Required

- Temperature Range Ambient

- Accuracy 0.01 mm gap accuracy

- Measurement Range 75 m 300 m (approximate, varies by model)

- Click to view more

Sag Index Applicators Price And Quantity

- 1 Piece

- 5000 INR

- ASTM D4400, ISO 16862

- Integrated with main applicator body

- R&D, quality testing in paint industry

- Up to 2 mm

- Satin/matte for reduced glare

- Approx. 75 mm

- Polished

- Requires cleaning after each use to avoid residue accumulation

Sag Index Applicators Product Specifications

- 75 m 300 m (approximate, varies by model)

- Stainless Steel

- Ambient

- 0.01 mm gap accuracy

- Manual

- Not Required

- Varies by model; typically 150x20x20 mm

- Sag Index Applicator

- Manual

- Paint/coating sag resistance measurement

- Multiple gap heights for creating precise sag index patterns

- ASTM D4400, ISO 16862

- Integrated with main applicator body

- R&D, quality testing in paint industry

- Up to 2 mm

- Satin/matte for reduced glare

- Approx. 75 mm

- Polished

- Requires cleaning after each use to avoid residue accumulation

Sag Index Applicators Trade Information

- 5-10 Piece piece Per Month

- 6-8 Week

Product Description

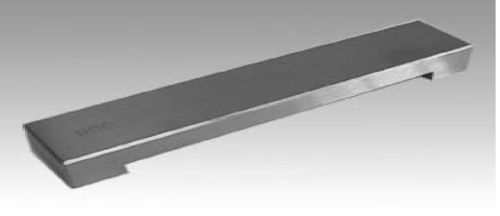

Sag Index Applicators

This applicator allows the sag resistance of coating to be visually evaluated. It applies a series of 10 parallel tracks of the coating to the substrate.

Each adjacent track is thicker than the last. This test panel is then held vertically. The sag index value is determined as being the first track which does not sag into the one below (with the thickest at the bottom). The step interval between each track indicates a sag of 25%.

Now conforming to new International Standard BS / ISO 16862

| SKU | Name | |

|---|---|---|

1108/275 | 90mm film width, step range 50-275µm in 25µm steps. | |

1108/475 | 90mm film width, step range 250-475µm in 25µm steps. | |

1108/675 | 90mm film width, step range 450-675µm in 25µm steps. |

Precision Meets Durability

Crafted from stainless steel, our sag index applicator offers reliability and longevity with 0.01 mm gap accuracy. The integrated handle design enhances stability, while the satin/matte finish reduces glare during measurement. Multiple gap heights allow for highly accurate and consistent sag resistance testing, making it the preferred choice for professionals in the paint industry.

Designed for Easy Maintenance

After each use, cleaning the applicator is essential to prevent residue accumulation. Its polished surfaces make maintenance swift and efficient, ensuring that precise results are achieved every time. A simple manual cleaning procedure preserves calibration integrity for consistent performance in R&D and quality testing applications.

FAQs of Sag Index Applicators:

Q: How is the Sag Index Applicator used in paint sag resistance measurement?

A: To measure sag resistance, apply the paint onto a substrate using the applicators precise gap heights, then observe sag behavior. The tools accuracy ensures reproducible results crucial for paint formulation and quality control.Q: What benefits does the satin/matte surface finish offer during testing?

A: The satin/matte finish reduces glare, providing clearer visibility when applying and measuring paint patterns, which improves accuracy and comfort for the operator in laboratory environments.Q: Where can this applicator be used, and for which types of testing is it ideal?

A: It is best used in R&D labs and quality control departments within the paint and coatings industry, supporting ASTM D4400 and ISO 16862 compliance in sag index testing procedures.Q: What is the recommended cleaning process for maintaining the applicator?

A: Clean the applicator manually after each use with suitable solvents to remove paint residue, ensuring gap heights remain precise and free of buildup. Dry thoroughly before storing.Q: What are the maximum substrate and measurement ranges for this applicator?

A: The tool accommodates substrates up to 2 mm thick and a measurement range approximately between 75 m and 300 m, depending on the model, allowing versatility in test specimens.Q: How does integrated handle design impact usability?

A: With the handle seamlessly part of the main body, users experience enhanced grip and stability, reducing fatigue and facilitating consistent manual application for reliable testing results.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese Get A Quote

Get A Quote