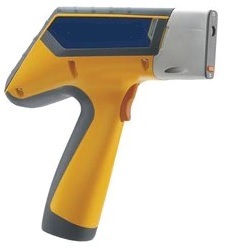

NAC2100G General Metal Analyzer

1000 INR/Piece

Product Details:

- Resolution 0.001%

- Interface Type USB, LAN

- Display Type Digital LCD Touch Screen

- Mounting Type Portable/Desktop

- Specimen Size Customized

- Equipment Type General Metal Analyzer

- Test Range General metals

- Click to view more

X

NAC2100G General Metal Analyzer Price And Quantity

- 1000 INR/Piece

- 100.00 - 1000.00 INR/Piece

- 3-4 Piece

- High precision arc/spark source

- English/Chinese

- Down to ppm level

- Manual/Auto

- 340 × 260 × 230 mm

- Dedicated high-performance software

- Yes, external printer support

- Minimal or none

- Fe, Cu, Al, Zn, Ni, Sn, Pb, Mg etc.

- User programmable, automatic

- Overheating auto-off, surge protection

- Integrated memory up to 10000 results

- Spectroscopy

NAC2100G General Metal Analyzer Product Specifications

- Standard

- 50/60 Hz

- 220V/110V AC, 50/60 Hz

- Single/Multiple

- Standard

- Digital

- 85%

- High

- Semi Automatic

- 0.1-0.7 MPa

- AC 220V/110V

- Customized

- Portable/Desktop

- General metals

- General Metal Analyzer

- Instant

- 0.001%

- USB, LAN

- Alloy & Metal Identification

- Standard

- Digital LCD Touch Screen

- Extensive (Ferrous & Non-ferrous metals)

- 28 kg

- 0.05%

- Standard

- Standard

- Metal composition analysis

- Portable, Quick Measurement, Multi-metal Analysis

- 10C - 40C

- High precision arc/spark source

- English/Chinese

- Down to ppm level

- Manual/Auto

- 340 × 260 × 230 mm

- Dedicated high-performance software

- Yes, external printer support

- Minimal or none

- Fe, Cu, Al, Zn, Ni, Sn, Pb, Mg etc.

- User programmable, automatic

- Overheating auto-off, surge protection

- Integrated memory up to 10000 results

- Spectroscopy

NAC2100G General Metal Analyzer Trade Information

- MUMBAI

- 3-4 Piece Per Day

- 3-4 Week

- All India

- ISO CERTIFICATE : 9001:2015

Product Description

Get immediate, nondestructive elemental analysis of alloy materials from titanium to nickel with the NAC2100G General Metal Analyzer. The NAC2100G analyzer is a practical, cost-effective solution that offers fast analysis for general alloy identification, basic fabrication, and scrap metal sorting. This high value, high performance analyzer features advanced electronics yet it is ruggedly built to withstand the harshest environments, in the field or on the shop floor.

The value choice to ensure accuracy, precision, and ease of use:

- Precise elemental analysis of alloy materials

- Very easy to use even by non-technical personnel

- Ruggedly designed for the most challenging industrial environments, and sealed against moisture and dust

- Completely nondestructive test

- Ergonomically designed

- Customizable menus with multiple language options and daylight-readable icons

- Standard analytical range of more than 25 elements from sulfur to uranium.

Advanced Spectroscopy for Multi-Metal Analysis

Harnessing cutting-edge arc/spark technology, the NAC2100G provides accurate results for a wide range of metals including iron, copper, aluminum, zinc, nickel, tin, lead, and magnesium. Its analysis method ensures excellent resolution and detection limits as low as ppm levels, making it suitable for both routine and demanding applications in metal composition assessment.

Convenient and Efficient Operation

The analyzer supports English and Chinese interfaces, allowing easy navigation on its digital LCD touch screen. Integrated data storage for 10,000 results, external printer support, and automation options enable streamlined workflows. Its user-programmable calibration and rapid response facilitate high throughput in busy environments, backed by robust safety features for reliable performance.

Flexible Application and Portability

Engineered for both portable and desktop use, the NAC2100G suits laboratory, production, and field settings. Its high-capacity, customizable specimen handling, and semi-automatic functionality allow quick identification and verification across a wide spectrum of metal types, making it an ideal solution for exporters, importers, manufacturers, suppliers, and traders.

FAQs of NAC2100G General Metal Analyzer:

Q: How does the NAC2100G General Metal Analyzer process samples for metal analysis?

A: This analyzer uses a high-precision arc/spark excitation source to induce emission from metal samples, which are then analyzed via spectroscopy. Minimal or no sample preparation is required, allowing for quick measurements and easy operation.Q: What types of metals and elements can be detected by the NAC2100G?

A: The instrument is designed for extensive analysis of ferrous and non-ferrous metals, including iron (Fe), copper (Cu), aluminum (Al), zinc (Zn), nickel (Ni), tin (Sn), lead (Pb), magnesium (Mg), and more, with detection limits down to ppm levels.Q: When is it necessary to calibrate the NAC2100G analyzer and how is it done?

A: Calibration can be performed automatically or programmed by the user for optimal accuracy. Regular calibration is recommended when changing sample types or after extended usage to ensure results remain within 0.05% precision.Q: Where can the NAC2100G be effectively utilized?

A: The analyzer is suitable for laboratories, manufacturing plants, industrial sites, and trading operations in metal industries. Its portable design allows for both desktop and on-site usage, offering flexibility for diverse applications.Q: What is the process for storing and printing test results?

A: Test results can be stored in the integrated memory, which accommodates up to 10,000 outcomes. For hard copies, the instrument offers a printer interface for external printer connection, supporting efficient data management and documentation.Q: How does the NAC2100G ensure safe operation during metal analysis?

A: Safety features include automatic shut-off in case of overheating and surge protection. These measures safeguard both the instrument and the samples, ensuring reliable performance under standard environmental conditions.Q: What are the main benefits of using the NAC2100G for alloy and metal identification?

A: Key advantages include rapid and precise multi-element analysis, minimal sample preparation, instant response time, user-friendly touch screen interface, semi-automatic operation, and robust data storageall contributing to improved productivity and confidence in metal composition verification.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese Get A Quote

Get A Quote