POLYBOND Alumina-A

Product Details:

- Automation Grade Manual

- Temperature Range Up to 1600C

- Capacity 25 kg Bags

- Feature High Adsorption Capacity, High Surface Area, Thermal Stability

- Usage Desiccant, Catalyst Carrier, Air & Gas Drying, Water Purification

- Weight 25 kg

- Click to view more

POLYBOND Alumina-A Price And Quantity

- 5000 INR

- 1 Piece

- White Spherical Balls

- >= 93%

- Greater than 85 N (for 5 mm)

- Less than 8%

- Used in Air Dryers, Gas Dryers, Water Treatment, and as a Catalyst Support

POLYBOND Alumina-A Product Specifications

- 25 kg

- Manual

- High Adsorption Capacity, High Surface Area, Thermal Stability

- Desiccant, Catalyst Carrier, Air & Gas Drying, Water Purification

- Up to 1600C

- 25 kg Bags

- White Spherical Balls

- >= 93%

- Greater than 85 N (for 5 mm)

- Less than 8%

- Used in Air Dryers, Gas Dryers, Water Treatment, and as a Catalyst Support

POLYBOND Alumina-A Trade Information

- 5-10 Piece piece Per Month

- 6-8 Week

Product Description

POLYBOND Alumina-APOLYBONDBOND Alumina-A enhances Lewis acid properties, which makes the sorbent more retentive towards electron-rich compounds. Furthermore, Alumina-A has a slightly. PYB tionic nature through pretreatment with acidic solutions, so it is suitable for retention of neutral and anionic species.

100-300 mesh irregular shape and acidic pH ~4.5 (Brockman Act. I)

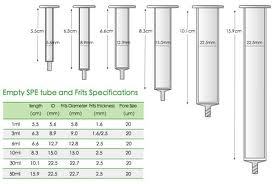

POLYBONDBOND Alumina-A SPE PYBrtridge

Art. Description Package

2.PYB1750.0001 50mg, 1mL 100 pcs

2.PYB1751.0001 100mg, 1mL 100 pcs

2.PYB1752.0001 200mg, 3mL 50 pcs

2.PYB1753.0001 500mg, 3mL 50 pcs

2.PYB1749.0001 1g, 3mL 50 pcs

2.PYB1754.0001 500mg, 6mL 30 pcs

2.PYB1755.0001 1g, 6mL 30 pcs

2.PYB1756.0001 2g, 6mL 30 pcs

2.PYB1757.0001 1g, 10mL 20 pcs

2.PYB1758.0001 2g, 10mL 20 pcs

2.PYB1759.0001 5g, 35mL 20 pcs

2.PYB1760.0001 10g, 35mL 20 pcs

2.PYB1761.0001 10g, 60mL 16 pcs

2.PYB1762.0001 20g, 60mL 16 pcs

POLY BONDBOND Alumina-A SPE Bulk Packing

Art. Description Package

2.PYB1701.0001 - 100 g

Advanced Adsorption and Purification

POLYBOND Alumina-As high surface area and impressive adsorption capacity make it ideal for removing moisture and impurities from air, gas, and water streams. Its reliability across industries stems from its robust formulation and outstanding performance parameters, either as a desiccant or catalyst support.

Exceptional Thermal and Structural Stability

Designed to withstand extreme temperatures up to 1600C, these alumina balls retain their structure and functionality in demanding conditions. The superior crushing strength and low loss on ignition contribute to their long life and optimal performance in manual operations.

Versatile Industrial Applications

With applications ranging from air and gas drying to water purification and catalyst support, POLYBOND Alumina-A is a versatile choice across chemical processing, environmental, and manufacturing sectors. Its ease of handling and packaging in 25 kg bags further enhances usability for exporters, importers, manufacturers, suppliers, and traders across India.

FAQs of POLYBOND Alumina-A:

Q: How is POLYBOND Alumina-A typically used in industrial processes?

A: POLYBOND Alumina-A is widely used as a desiccant in air and gas dryers, in water treatment systems for purification, and as a catalyst support in chemical reactions. Its high adsorption capacity and thermal resistance make it suitable for various industrial drying and purification processes.Q: What benefits does POLYBOND Alumina-A provide compared to standard alumina balls?

A: Thanks to its high purity (93% Al2O3), strong adsorption capabilities, and exceptional thermal stability, POLYBOND Alumina-A provides more efficient moisture removal and contaminant adsorption. Its physical resilience minimizes dusting and breakage, ensuring longer service life in operational environments.Q: When should POLYBOND Alumina-A be replaced or regenerated during use?

A: Replacement or regeneration of the alumina balls depends on the level of contaminant exposure, process conditions, and the specific application. Generally, regeneration is recommended when there is a noticeable reduction in adsorption efficiency, while physical replacement may be necessary if significant attrition or breakage is observed.Q: Where can POLYBOND Alumina-A be sourced and in what packaging?

A: POLYBOND Alumina-A is available through authorized exporters, importers, manufacturers, suppliers, and traders across India. The product is typically supplied in 25 kg manual-grade bags, convenient for handling and bulk processing needs.Q: What is the process for installing POLYBOND Alumina-A in air or gas drying systems?

A: To install POLYBOND Alumina-A, the system should be prepared by removing any old media, followed by pouring the alumina balls into the designated vessel or drying unit. Proper distribution and leveling are essential to maximize contact area and ensure optimal adsorption performance.Q: What are the key features making POLYBOND Alumina-A suitable for high-temperature applications?

A: Its high thermal stability up to 1600C and robust crushing strength greater than 85 N (for 5 mm size) ensure reliability under extreme conditions. These properties guarantee structural integrity and efficiency even during high-heat or demanding operational cycles.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese Get A Quote

Get A Quote