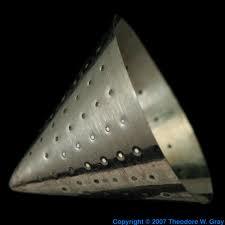

Platinum Micro Crucible

100 INR

Product Details:

- Temperature Resistance Up to 1700C (Approx.)

- Features Corrosion resistant, chemically inert, highly durable, precise mass, smooth finish

- Control Type Manual handling

- Shape Round or cylindrical, with tapered sides

- Type Micro Crucible

- Dimension (L*W*H) Available in various micro sizes (typically 5 ml to 30 ml capacities; custom on request)

- Equipment Type Laboratory Crucible

- Click to view more

X

Platinum Micro Crucible Price And Quantity

- 100 INR

- 1 , , Piece

- Mirror polished inside and outside

- 21.45 g/cm

- Research laboratories, industrial quality control, academic institutions

- Highly resistant to acids and fluxes (except fused alkalis and cyanides)

- Platinum crucibles withstand temperatures above 1700C

Platinum Micro Crucible Product Specifications

- Laboratory Crucible

- Manual handling

- Round or cylindrical, with tapered sides

- Up to 1700C (Approx.)

- Corrosion resistant, chemically inert, highly durable, precise mass, smooth finish

- Available in various micro sizes (typically 5 ml to 30 ml capacities; custom on request)

- Platinum (Pt)

- 99.95% Pure Platinum

- Micro Crucible

- Mirror polished inside and outside

- 21.45 g/cm

- Research laboratories, industrial quality control, academic institutions

- Highly resistant to acids and fluxes (except fused alkalis and cyanides)

- Platinum crucibles withstand temperatures above 1700C

Platinum Micro Crucible Trade Information

- Mumbai

- Cash Advance (CA), Telegraphic Transfer (T/T), Cash in Advance (CID)

- 5-10 , , Piece piece Per Day

- 1 Week

- North America, South America, Eastern Europe, Western Europe, Middle East, Africa, Australia, Asia, Central America

- All India

- ISO CERTIFICATE 9001:2005

Product Description

We are one of the foremost suppliers and exporters of the market, engaged in offering a superior range of Platinum Micro Crucible. These crucibles are made from top quality platinum at our vendors state of the art machining facility. Our Platinum Micro Crucible prevents the aggregation of particles in the center. Our crucibles are made available to clients in various sizes and dimensions so that customers' utmost satisfaction can be duly obtained.

Features:

- High temperature strength

- Excellent melting point

- Oxidation resistant

Specifications:

| No. | Capacity cc | Top Diameter mm | Height mm | Crucible (wt gm) | Lid (wt gm) |

| NAC 111 | 1 | 12.0 | 13 | 2.0 | 0.50 |

| NAC 112 | 3 | 17.0 | 19 | 4.5 | 1.50 |

| NAC 113 | 5 | 20.5 | 22 | 5.5 | 1.75 |

Superior Heat and Chemical Resistance

Crafted from ultra-pure platinum, these micro crucibles excel in environments requiring both high temperature tolerance (up to 1700C) and exceptional resistance to corrosive substances. Researchers and industry professionals trust their robust performance where ordinary vessels would fail.

Versatile Applications Across Multiple Sectors

Platinum Micro Crucibles serve a wide range of settings, including research laboratories, academic institutions, and industrial quality control departments. Their resilience and precision make them indispensable for gravimetric analysis, high-temperature reactions, and materials testing.

Precision Engineering and Customization

Engineered with precision, the crucibles feature smooth, mirror-polished interiors and exteriors to minimize sample loss and stickiness. Available in micro sizes from 5 ml to 30 ml, they can also be custom-sized to meet unique laboratory requirements.

FAQs of Platinum Micro Crucible:

Q: How should Platinum Micro Crucibles be handled during high-temperature experiments?

A: Platinum Micro Crucibles are best handled manually using appropriate tools such as tongs designed for high temperatures. Always allow the crucible to cool slightly before moving to prevent accidental burns and structural shock.Q: What makes these crucibles suitable for use with aggressive chemicals?

A: Owing to their 99.95% pure platinum composition, these crucibles exhibit exceptional chemical resistivity against acids and fluxes, making them reliable for reactions involving most corrosive agents, excluding fused alkalis and cyanides.Q: When is it most advantageous to use a platinum micro crucible instead of other materials?

A: Platinum Micro Crucibles are ideal when working with substances at elevated temperatures up to 1700C or with chemicals that might corrode lesser materials, ensuring result integrity and equipment longevity.Q: Where are platinum micro crucibles commonly implemented?

A: These crucibles are widely used in scientific research laboratories, academic classrooms, and industrial quality control settings, particularly where precise mass measurement and high corrosion resistance are necessary.Q: What is the standard process for cleaning and maintaining the mirror-polished crucibles?

A: After use, clean the crucible with distilled water and a soft brush to avoid scratches. For stubborn residues, employ mild acid treatments compatible with platinum to maintain its mirror finish and structural integrity.Q: What are the primary benefits of using platinum micro crucibles in laboratory analysis?

A: The key benefits include exceptional temperature resistance, chemical inertness, durability, a precisely measured mass, and smooth finishes that ensure minimal sample retention and accurate results.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese Get A Quote

Get A Quote