Manual Syringes

Product Details:

- Equipment Type Syringe

- Use Type Manual

- Needle Material Stainless Steel

- Grade Medical Grade

- Nozzle Luer Lock / Luer Slip

- Usage Medical / Laboratory

- Sterilized Yes

- Click to view more

Manual Syringes Price And Quantity

- 5000 INR

- 1 Piece

- Blister/PE Wrapped

- Yes

- Universal with Standard Needles

- Clear and Accurate

- Yes

- Non-pyrogenic, Non-toxic

- No

- 5 Years

- Yes

- Medical Grade Polypropylene

- High Transparency Barrel

- Varies (Transparent, White, or Colored)

Manual Syringes Product Specifications

- Yes

- Syringe

- Manual

- Yes

- Autoclave / Ethylene Oxide (EO) Gas

- Luer Lock / Luer Slip

- No

- Medical / Laboratory

- Stainless Steel

- 1 ml, 2 ml, 5 ml, 10 ml, 20 ml, 50 ml

- Medical Grade

- Blister/PE Wrapped

- Yes

- Universal with Standard Needles

- Clear and Accurate

- Yes

- Non-pyrogenic, Non-toxic

- No

- 5 Years

- Yes

- Medical Grade Polypropylene

- High Transparency Barrel

- Varies (Transparent, White, or Colored)

Manual Syringes Trade Information

- 5-10 Piece piece Per Month

- 6-8 Week

Product Description

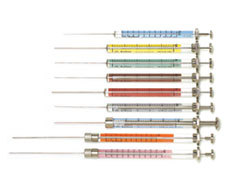

Manual Syringes

Brilliant color coded barrels facilitate syringe volume identification while making life in the lab more colorful. Whether performing manual dilution, extraction, enhancement or sample preparation, our manual syringes help simplify and boost productivity along every step of your sample processing. Each denomination (0.5 µL to 50 mL) features a distinct color boldly embossed on the glass barrel for faster and easier identification.

|

|

| Volume | Description | Needle/Length/Tip | ||

|---|---|---|---|---|---|---|

|

|

| 0 | Replacement needle | 25/bevel tip | 3/pk | |

|

|

| 0 | Replacement needle | 23/bevel tip | 3/pk | |

|

|

| 0 | Replacement needle | 23/bevel tip | 3/pk | |

|

|

| 1.0 | Removable | 23/50 mm/bevel tip | 1/ea | |

|

|

|

| Luer Lok needle | 23/50/bevel tip |

| 3/pk |

|

|

| 1.0 | Luer Lok valve | Luer Lok valve/50 mm or 2 in | 1/ea | |

|

|

| 1.0 | Replacement plunger with PTFE tip for 1 mL syringes |

|

| |

|

|

| 1.0 | Fixed | 22/50 mm/bevel tip | 1/ea | |

|

|

| 2.5 | Removable | 23/50 mm/bevel tip | 1/ea | |

|

|

| 2.5 | Replacement plunger with PTFE tip for 2.5 mL syringes |

|

|

Exceptional Safety and Hygiene

Our syringes are produced using high-grade medical materials and strictly adhere to safety standards. Each unit is latex-free, sterile, and single-use, effectively minimizing any risk of cross-contamination or patient reaction. The non-pyrogenic and non-toxic construction guarantees a safe experience during every use in both medical and laboratory settings.

Versatile Design and Universal Compatibility

Engineered with universal Luer Lock and Luer Slip nozzles, our syringes are compatible with standard needles, enhancing their adaptability across various applications. The color of the plunger may vary, allowing for quick identification, while the high-transparency barrel and clear markings ensure precise dosing every time.

Reliable Packaging and Extended Shelf Life

Every syringe is carefully packaged in blister or PE wrap, maintaining its sterility throughout transport and storage. With a five-year shelf life, these syringes offer both peace of mind and convenience for medical professionals and laboratories, ensuring reliable performance whenever needed.

FAQs of Manual Syringes :

Q: How should manual syringes be used for medical or laboratory applications?

A: Manual syringes are designed for single-use and should be operated according to standard protocols. Attach the appropriate sterile standard needle using the Luer Lock or Luer Slip nozzle, draw or dispense the desired volume as indicated by the clear markings, then safely dispose of the syringes after use to maintain hygiene.Q: What benefits does a high-transparency barrel offer in these syringes?

A: A high-transparency barrel allows for accurate visual verification of fluid volume and bubble detection, which is critical for patient safety and precise measurement in both medical and laboratory environments.Q: When is it most appropriate to use disposable, non-recyclable syringes?

A: These syringes are ideal for situations requiring sterile, single-use equipment, such as patient injections, sample withdrawals, or laboratory tasks to eliminate risks of cross-infection and ensure precise results.Q: Where are these manual syringes manufactured and exported from?

A: These manual syringes are produced in India and can be supplied globally, serving as products of choice for exporters, importers, manufacturers, suppliers, and traders involved in medical and laboratory supply chains.Q: What kind of sterilization process do the syringes undergo before packaging?

A: The syringes are sterilized using either autoclave or Ethylene Oxide (EO) gas methods before being individually blister or PE wrapped, ensuring they remain sterile and safe to use until their expiration date.Q: Why are these syringes not suitable for autoclaving after use?

A: As single-use, disposable syringes that are not designed for post-use sterilization or recycling, attempting to autoclave them can compromise material integrity and safety, making proper disposal mandatory after one-time use.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese Get A Quote

Get A Quote