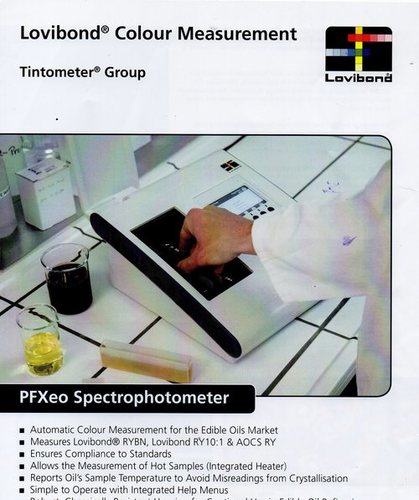

PFXeo spectrophotometer

Product Details:

- Accuracy Repeatability < 0.1 E

- Display Type Digital LCD display

- Shape Rectangular

- Power Supply Mains supply

- Temperature Resistance Ambient room temperature

- Control Type Microprocessor control

- Features Preinstalled industry scales, password protection, large clear display, measurement log

- Click to view more

X

PFXeo spectrophotometer Price And Quantity

- 3 , , Piece

- Up to 80% non-condensing

- Conforms to international standards for color measurement

- Automatic calibration routines

- < 20 seconds

- 10 nm

- Lovibond, AOCS Tintometer, Gardner, Saybolt, ASTM, Iodine, Hazen/APHA, and others

- > 400 results

- 10, 20, & 40 mm cell compatibility

- USB, RS232, and LAN interfaces

- Multi-language menu navigation

- 6.8 kg

- Minimal required for analysis

- 420730 nm

- Tungsten-halogen, long-life

- Comes with sample cells and cleaning cloth

PFXeo spectrophotometer Product Specifications

- Preinstalled industry scales, password protection, large clear display, measurement log

- ABS plastic housing

- Spectrophotometer

- Microprocessor control

- Color measurement for oils, chemicals, and transparent liquids

- Mains supply

- Ambient room temperature

- 25 W max

- Rectangular

- 100240 V AC, 50/60 Hz

- Corrosion resistant, solvent-proof surfaces

- 510 mm x 260 mm x 185 mm

- Digital LCD display

- Bench-top Spectrophotometer

- Repeatability < 0.1 E

- Up to 80% non-condensing

- Conforms to international standards for color measurement

- Automatic calibration routines

- < 20 seconds

- 10 nm

- Lovibond, AOCS Tintometer, Gardner, Saybolt, ASTM, Iodine, Hazen/APHA, and others

- > 400 results

- 10, 20, & 40 mm cell compatibility

- USB, RS232, and LAN interfaces

- Multi-language menu navigation

- 6.8 kg

- Minimal required for analysis

- 420730 nm

- Tungsten-halogen, long-life

- Comes with sample cells and cleaning cloth

PFXeo spectrophotometer Trade Information

- Mumbai

- 3-4 , , Piece Per Day

- 3-4 Week

- Western Europe, Australia, North America, Eastern Europe, Middle East, Central America, Africa, South America, Asia

- All India

- ISO CERTIFICATE 9001:2005

Product Description

PFXeo Spectrophotometer

- Automatic Colour Measurement for the Edible OIls MArket

- Measures RYBN, RY 10:1 & AOCS RY

- Ensures Compliance to Standards

- Allow the Measurement of Hot Samples (Integrated Heater)

- Reports Oil's Sample Temperature to Avoid Misreadings from Crystallisation

- Simple to Operate with Integrated Help Menus

- Robust, Chemically Resistant Housing for Continual Use in Edible Oil Refineries

- Aluminium Casing - 100% Recyclable and Sustainable

- Sealed Units & Removable Sample Chamber (Oil Spillages will Not Impact Accuracy)

- New Technology Giving High Resolution, Repeatability, Reliability and Accuracy

Versatile and Reliable Color Measurement

The PFXeo spectrophotometer provides dependable color analysis for a wide array of transparent liquids, such as oils and industrial chemicals. Its compatibility with multiple path lengths and internationally recognized color scales ensures versatility, making it suitable for laboratory, production, and quality control settings. Robust construction and quick measurement cycles enhance efficiency without compromising on accuracy.

User-Friendly Operation and Advanced Features

Equipped with an intuitive, multilingual menu and digital LCD display, the PFXeo offers seamless navigation and operation for users worldwide. Automatic calibration routines and password protection bolster security and reliability. The internal memory stores over 400 results, while measurement logs and preinstalled industry scales ensure compliance and traceability.

Designed for Practicality and Industry Standards

With solvent-proof, corrosion-resistant surfaces and an ABS plastic housing, the PFXeo stands up to demanding environments. It provides interfaces for easy data export, supports power supply flexibility (100240 V AC), and comes with essential accessories. The instruments adherence to international standards gives manufacturers, exporters, and suppliers confidence in global compatibility and performance.

FAQs of PFXeo spectrophotometer:

Q: How do I calibrate the PFXeo spectrophotometer for routine use?

A: The PFXeo features automatic calibration routines, enabling you to perform scheduled calibrations via the microprocessor-controlled interface with minimal user intervention. Simply access the calibration option from the menu, and the device will guide you through the process, ensuring continued measurement accuracy.Q: What types of samples and color scales can the PFXeo analyze?

A: The instrument is engineered for transparent liquids such as oils and chemicals. It supports a broad selection of color scales, including Lovibond, AOCS Tintometer, Gardner, Saybolt, ASTM, Iodine, Hazen/APHA, and others, making it ideal for diverse laboratory and industrial applications.Q: When is it necessary to perform maintenance or cleaning on the PFXeo?

A: Routine maintenance involves periodic cleaning of sample cells and the optical compartment, especially after frequent or continuous use. The included cleaning cloth and solvent-proof materials make upkeep straightforward, ensuring optimal performance and data integrity.Q: Where can I access or export my measurement data from the PFXeo?

A: Measurement results can be stored internally (over 400 results) and exported via USB, RS232, or LAN interfaces. This flexibility ensures seamless integration with laboratory information management systems or direct data retrieval on connected devices.Q: What is the process for measuring a sample with the PFXeo spectrophotometer?

A: To measure a sample, select the appropriate path length cell (10, 20, or 40 mm), fill it with the minimal required sample volume, and place it in the instrument. Use the multi-language menu to choose the color scale and initiate the measurement. Results will appear digitally on the LCD display in under 20 seconds.Q: How does the PFXeo spectrophotometer benefit my laboratory or production facility?

A: By delivering rapid, repeatable measurements (< 0.1 E) and supporting compliance with international standards, the PFXeo streamlines color quality control processes. Its robust construction, automation, and data management features help boost productivity while reducing operator error and training needs.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese Get A Quote

Get A Quote