LASER PARTICLE COUNTER.- PC-2300

Product Details:

- Capacity 2.83 L/min

- Automation Grade Automatic

- Frequency 50/60 Hz

- Measurement Range 0.3 10 m (particle size)

- Core Components Laser sensor, sampling pump, microprocessor

- Accuracy 10%

- Temperature Range 10C to 40C

- Click to view more

LASER PARTICLE COUNTER.- PC-2300 Price And Quantity

- 5000 INR

- 1 Piece

- Audible and visual alarm for threshold limit

- More than 4 hours (battery mode)

- Pharmaceutical, Hospital, Laboratory, and Cleanroom monitoring

- 6 channels (0.3, 0.5, 1.0, 3.0, 5.0, 10.0 µm)

- Splash/Dust resistant outer body (IP54 equivalent)

- 1 second to 99 minutes

- Factory calibrated and ISO compliant

- USB and RS232

- Data logger with up to 10000 records

LASER PARTICLE COUNTER.- PC-2300 Product Specifications

- 220V

- 220 x 140 x 60 mm

- 50/60 Hz

- Automatic

- 10C to 40C

- Laser Particle Counter

- Laser sensor, sampling pump, microprocessor

- 10%

- Rechargeable Lithium Battery

- 2.83 L/min

- 0.3 10 m (particle size)

- 2.5 kg

- LCD Display

- Airborne particle counting in cleanrooms and controlled environments

- Audible and visual alarm for threshold limit

- More than 4 hours (battery mode)

- Pharmaceutical, Hospital, Laboratory, and Cleanroom monitoring

- 6 channels (0.3, 0.5, 1.0, 3.0, 5.0, 10.0 µm)

- Splash/Dust resistant outer body (IP54 equivalent)

- 1 second to 99 minutes

- Factory calibrated and ISO compliant

- USB and RS232

- Data logger with up to 10000 records

LASER PARTICLE COUNTER.- PC-2300 Trade Information

- 5-10 Piece piece Per Month

- 6-8 Week

Product Description

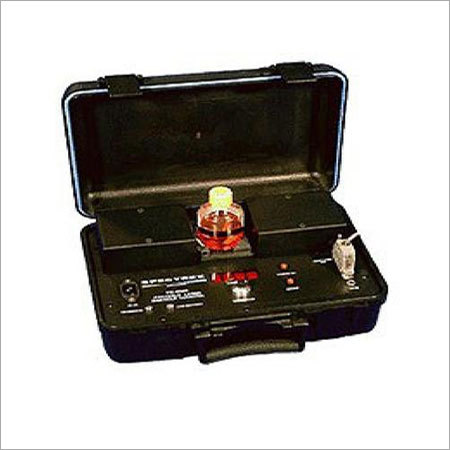

LASER PARTICLE COUNTER.- PC-2300Features :

Complete Portability. Use it Anywhere!

Easy Do-It-Yourself Calibration (sealed standards provided)

Compact and Rugged (floats)

Quickly Counts & Sizes (16 seconds min.)

Custom Easy-to-Use Software

Eliminates Sample Flushing

Built in magnetic stirrer

Operational Theory :

Utilizing the principle of near angle light scatter, a revolving laser beam passes through the walls of a glass container or a flow-thru cell. When it is directed through a central sensitive zone the PC-2300 not only counts the particles in suspension, but tabulates their size as well. The analog signals generated by the light pulses are routed to a computer and digitized.

Calibration :

Spectrex provides three sealed calibration standards with each unit. Each standard contains a precise number of NIST traceable polystyrene spheres of known size in suspension and are sealed with inert Argon gas These standards have a proven stability of more than 2 years and pro-vide efficient calibration within 10 minutes.

Applications :

- Field Hydrology

- Water Treatment Plants

- Hydraulic Fluids and Oil QC

- Silts and Sediment Sizing

- University Laboratories

- Pharmaceutical Manufacturers

- Oil Refineries and On-site drilling

- Bottling & Beverage Operations

- Oceanographic Studies

- Liquid Chromatography Solvent QC

- Cooling Power and Waste Water Filter Efficiency

- Particle Agglomeration Studies

- Particle Settling Characteristics

- Corrosive Chemical and Solvent Sizing

- Vial and Ampule Inspection

- Deionized Water and Acid Testing

- Cell Counting

Specifications :

- Size : 9.5 x 14.5 x 6

- Weight: 15 lbs

- Typical Bottle Size: 15-60 mm inside diameter

- Bottle Material: Transparent, scratch-free glass

- Detectable Particle Size: From 0.5m - 100m.

- Power: 115v 60Hz AC, 12v car jack or internal battery (battery run time is 5 hours)

Versatile Particle Monitoring

The PC-2300 particle counter accommodates various applications, including cleanroom validation, hospital air quality audits, and pharmaceutical production monitoring. Its six selectable channels enable accurate size discrimination, empowering users to address different regulatory and operational requirements with confidence. Both manufacturers and safety teams benefit from its intuitive automation and portability.

Robust Data Management and Connectivity

With a built-in data logger capable of storing up to 10,000 samples, users can perform seamless data reviews and export results using USB or RS232 interfaces. The LCD display guides users through sampling and status checks, ensuring every measurement is recorded and retrievable for compliance purposes. This system supports thorough reporting and traceability in regulated industries.

Durable Design for Demanding Environments

IP54-rated splash and dust-resistant construction protects the PC-2300 during rigorous field or laboratory use. This counter operates reliably across typical temperature ranges and provides more than four hours of battery-powered functionality, making it suitable for prolonged monitoring in various settings. Its sturdy frame, laser sensor technology, and accurate measurement capabilities add significant value to operational efficiency.

FAQs of LASER PARTICLE COUNTER.- PC-2300:

Q: How does the PC-2300 laser particle counter measure airborne particles?

A: The PC-2300 uses a high-sensitivity laser sensor combined with a precision sampling pump to draw air at a rate of 2.83 L/min. It detects and counts particles across six size channels, providing accurate readings for particle sizes ranging from 0.3 to 10.0 m.Q: What types of environments are suitable for using the PC-2300?

A: This particle counter is ideal for pharmaceutical facilities, hospitals, laboratories, and cleanrooms where monitoring airborne contamination is critical for compliance, safety, and product quality.Q: When should the alarm function be used, and how does it alert users?

A: The alarm feature should be enabled when a maximum particle concentration limit is set. If the measured value exceeds the threshold, the PC-2300 emits both audible and visual alerts to notify users immediately, helping prevent contamination events.Q: Where does the PC-2300 store its recorded data and how can I access it?

A: The instruments internal data logger stores up to 10,000 measurements. Data can be accessed and exported via the USB and RS232 communication interfaces, allowing for convenient data management and analysis on computers and external systems.Q: What is the typical process for calibrating and maintaining this device?

A: The PC-2300 is factory calibrated according to ISO standards, ensuring reliable performance upon delivery. Routine cleaning and proper handling of the splash/dust-resistant body helps maintain longevity. For recalibration, users should follow manufacturer guidelines or contact authorized service centers.Q: How do the selectable sampling times enhance usage flexibility?

A: Users can set sampling times anywhere from 1 second to 99 minutes, tailoring the monitoring process to specific environmental conditions or operational requirements. This flexibility supports a wide range of applications, from quick spot checks to continuous environmental monitoring.Q: What are the overall benefits of using the PC-2300 in regulated environments?

A: Adopting the PC-2300 improves air quality assurance, supports compliance with stringent standards, and provides fast, accurate data for risk assessment. Its reliable automation, alarm features, and data management capabilities streamline environmental control protocols and documentation.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese Get A Quote

Get A Quote