Krebs Viscometer

Product Details:

- Core Components Motor, Display, Spindle

- Temperature Range Room Temperature up to 50C

- Power Source Electric

- Accuracy 1% of Full Scale

- Measurement Range 40 to 141 KU (Krebs Units), equivalent to 32 1,090 cP

- Frequency 50/60 Hz

- Voltage 220 V AC

- Click to view more

Krebs Viscometer Price And Quantity

- 5000 INR

- 1 Piece

- USB / RS232

- <80% RH

- 75 mm

- 200 RPM

- 0.1 KU / 1 cP

- Adhesives, Varnishes, Chemical Industry

- 500 ml

- Factory Calibrated, User Calibration Possible

- 10C 40C

Krebs Viscometer Product Specifications

- Stainless Steel & ABS

- 7 kg

- 220 V AC

- Paint, Coating and Ink Viscosity Measurement

- 50/60 Hz

- 1% of Full Scale

- Digital

- Electric

- 220 x 360 x 530 mm

- Room Temperature up to 50C

- Motor, Display, Spindle

- 40 to 141 KU (Krebs Units), equivalent to 32 1,090 cP

- USB / RS232

- <80% RH

- 75 mm

- 200 RPM

- 0.1 KU / 1 cP

- Adhesives, Varnishes, Chemical Industry

- 500 ml

- Factory Calibrated, User Calibration Possible

- 10C 40C

Krebs Viscometer Trade Information

- 5-10 Piece piece Per Month

- 6-8 Week

Product Description

Krebs Viscometer

Features

Range: 54-140 KU (75-1000 g.)

Sturdy mechanical assembly & easy maintenance

Easy to read speed indication

Good value for money

Standard package: Viscometer, paddle rotor,

1 pint (500 ml) / 85 mm can,

Set of 7 weights (2 x 5g, 1 x 10g, 1 x 25g, 1 x 50g, 2 x 100g,

1 x 200g, 1 x 500g), AC/DC 12V adapter (for digital version)

Information

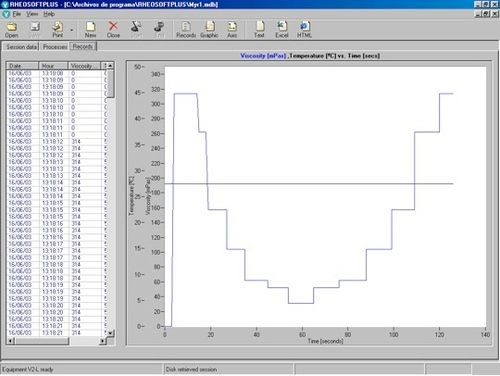

This traditional KREBS viscometry instrument uses a rotating paddle driven by falling weights to determine the paint viscosity. The viscosity value in Krebs units can be easily converted using the table supplied or by calculation by formula from the resultant value of total weight required to reach 200 rpm.The robust and simple construction of this viscometer allows it to be used in various environments.

2 versions available: with tachometer or with stroboscope.

Digital Precision for Viscosity Measurements

The Krebs Viscometer features a robust digital display and advanced spindle system, delivering highly accurate readings for viscosity, crucial in paint, ink, coating, and chemical industries. With a measurement range from 40 to 141 KU, it addresses rigorous quality demands, ensuring optimal consistency and product performance during manufacturing and testing processes.

User-Friendly Operation and Calibration

This device supports both factory and user calibration, making it adaptable to specific laboratory standards. Its straightforward controls and sample handling facilitate routine viscosity checks, while the convenient USB/RS232 data output streamlines recordkeeping and analysis. The viscometer is constructed for durability, with stainless steel and ABS materials ensuring longevity in diverse industrial environments.

FAQs of Krebs Viscometer:

Q: How is the Krebs Viscometer operated and what materials can it test?

A: The instrument operates electrically at a spindle speed of 200 RPM. It is suitable for testing viscosity in paints, coatings, inks, adhesives, and varnishes, making it a versatile solution for multiple applications in chemical and allied industries.Q: What is the process for calibrating the viscometer?

A: The viscometer comes factory calibrated for immediate use, but users have the option to perform additional calibration as needed. Calibration can be done according to laboratory standards and sample requirements, ensuring reliable and accurate measurements.Q: When should a user perform user calibration?

A: User calibration is recommended when switching between different types of samples or as part of routine equipment maintenance to ensure ongoing measurement accuracy, especially if testing materials with varying viscosities.Q: Where can the viscometer be used effectively?

A: Thanks to its ambient operating range of 10C to 40C and humidity tolerance below 80% RH, the Krebs Viscometer is ideal for laboratory use, factory floors, or quality control stations in paint, chemical, or coating facilities.Q: What are the benefits of the viscometers USB/RS232 data output?

A: The USB and RS232 data output interfaces simplify the process of transferring measurement results to computers or data loggers, enhancing productivity and supporting robust reporting and compliance needs.Q: How does the viscometer ensure precise viscosity readings?

A: With an accuracy of 1% of full scale and a resolution of 0.1 KU/1 cP, results are highly reliable. The digital display and factory calibration contribute to reducing human error and maintaining consistency in batch processes and quality control.Q: What sample container size and equipment dimensions should the user prepare?

A: The sample cup has a volume of 500 ml, suitable for a 75 mm diameter container. The device itself measures 220 x 360 x 530 mm, so ensure proper workspace for operation and safety during measurements.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese Get A Quote

Get A Quote