ASTM D-1200 Flow Cup Viscometers

Product Details:

- Capacity 50 ml (standard); available in various cup sizes as per ASTM D-1200 specifications

- Power Source Manual (No Power Required)

- Temperature Range Ambient

- Accuracy 3% of Reading

- Core Components Cup, Stand, Leveling Screws, Thermometer Clamp

- Automation Grade Manual

- Feature Portable, Easy to Use, Precise Flow Measurement

- Click to view more

ASTM D-1200 Flow Cup Viscometers Price And Quantity

- 5000 INR

- 1 Piece

- 2 mm, 3 mm, 4 mm (as per cup size)

- Polished Stainless Steel

- Disassemblable for Easy Cleaning

- Paint, Ink, Varnish, Coating, Chemical, Petrochemical Industries

- Seconds (Efflux Time), Centistokes (cSt) with conversion

- Leveling Base, Calibration Certificate, Operation Manual

- Manual Efflux Measurement (Stopwatch not included)

- ASTM D-1200, ISO 2431

- Ford Cup No. 2, 3, 4 (as per ASTM standard)

ASTM D-1200 Flow Cup Viscometers Product Specifications

- Stainless Steel Cup with Brass or Stainless Steel Body

- 3% of Reading

- Laboratory and Industrial Viscosity Measurements

- Flow Cup Viscometer

- Height Approx. 180 mm; Diameter Approx. 70 mm

- 50 ml (standard); available in various cup sizes as per ASTM D-1200 specifications

- Approximately 350g

- Ambient

- Manual (No Power Required)

- N/A (Manual Instrument)

- 20-1200 cSt (depending on cup size)

- Analog (Direct Flow Measurement)

- Portable, Easy to Use, Precise Flow Measurement

- ASTM D-1200

- Manual

- Cup, Stand, Leveling Screws, Thermometer Clamp

- 2 mm, 3 mm, 4 mm (as per cup size)

- Polished Stainless Steel

- Disassemblable for Easy Cleaning

- Paint, Ink, Varnish, Coating, Chemical, Petrochemical Industries

- Seconds (Efflux Time), Centistokes (cSt) with conversion

- Leveling Base, Calibration Certificate, Operation Manual

- Manual Efflux Measurement (Stopwatch not included)

- ASTM D-1200, ISO 2431

- Ford Cup No. 2, 3, 4 (as per ASTM standard)

ASTM D-1200 Flow Cup Viscometers Trade Information

- 5-10 Piece piece Per Month

- 6-8 Week

Product Description

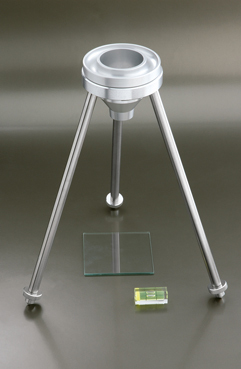

These types of flow cups are available in two options: with or without handle. The cups without handle can be supplied separately or with an adjustable stand that includes a precision level and an overflow glass draw plate. The handle types are fitted dir

Features

Flow cup viscometers provide kinematic viscosity data. The measured kinematic viscosity is generally expressed in seconds (s) flow time when the fluid is flowing through an orifice at a specified temperature. Thanks to the conversion equations the viscosity is calculated from the flow time to centistokes (cSt). The calibration certificates are supplied with the cups.

According to the standards, there are several viscosity ranges available from 5 cSt. Flow cups made of anodized aluminium body with a stainless steel orifice.

Ensuring the accuracy of the test results, we recommend a periodic calibration check. You can check the viscosity results using the standard oils specially manufactured for these kind of viscometers (available under request), or sending the instrument to our calibration laboratories.

Industries like paint, ink, varnishes and similar products use this very easy to use flow cups to quickly calculate the viscosity.

| Code | Model | Bore mm | Viscosity range (cSt) |

|---|---|---|---|

| FCA002 | Flow Cup Viscometer 2 ASTM D-1200 | 2.53 | 25 to 120 |

| FCA003 | Flow Cup Viscometer 3 ASTM D-1200 | 3.40 | 40 to 220 |

| FCA004 | Flow Cup Viscometer 4 ASTM D-1200 | 4.12 | 70 to 370 |

| FCA005 | Flow Cup Viscometer 5 ASTM D-1200 | 5.20 | 200 to 1,200 |

| FCS | Tripod Support for Flow Cup Viscometer | ||

| FCS-GL | Ergonomic Support for Flow Cup Viscometer |

Precision Viscosity Measurement for Industrial Fluids

Engineered to meet the stringent standards of ASTM D-1200 and ISO 2431, this flow cup viscometer offers reliable viscosity measurement ideal for quality control in laboratories and production environments. Its manual operation delivers direct, analog readings based on efflux time or converted centistokes, catering to a wide viscosity range by using interchangeable Ford Cups.

Comprehensive Kit and User-Friendly Operation

Each viscometer includes essential accessories: a leveling base for accurate setup, calibration certificate for compliance, and an operation manual for ease of use. The stainless steel cup and body ensure durability, while the instruments design allows for straightforward assembly, disassembly, and cleaning, facilitating maintenance and consistent performance.

Adaptable Applications and Portability

With its manual operation and compact design, the ASTM D-1200 viscometer proves exceptionally portable and convenient for both laboratory and on-site industrial applications. It accommodates diverse measurement needs across paint, ink, coatings, and chemical industries, enabling precise monitoring and quality control without the need for external power sources.

FAQs of ASTM D-1200 Flow Cup Viscometers:

Q: How does the ASTM D-1200 Flow Cup Viscometer measure viscosity?

A: The viscometer measures viscosity by manually timing the flow (efflux) of a 50 ml fluid sample through a specified orifice in the Ford Cup. The efflux time, recorded in seconds, can then be converted to centistokes (cSt) using provided tables for different cup sizes as per ASTM standards.Q: What types of fluids can be tested using this viscometer?

A: This viscometer is suitable for measuring the viscosity of paints, inks, varnishes, coatings, chemicals, and petrochemical products, making it ideal for laboratory and industrial quality control across multiple sectors.Q: When should calibration of the viscometer be performed?

A: Calibration should be checked before initial use and periodically during regular operation, especially after cleaning or component replacement. A calibration certificate is included with the instrument for documentation and compliance.Q: Where can the ASTM D-1200 Flow Cup Viscometer be used?

A: The instrument is designed for use in laboratories and industrial settings where manual viscosity measurement is required. Its portability and manual operation also make it suitable for on-site testing at factories and processing plants.Q: What is the cleaning and maintenance process for this viscometer?

A: Cleaning is straightforward due to its disassemblable design. The cup and orifices can be removed, washed, and dried to prevent residue buildup, ensuring accurate measurements and prolonging the instruments lifespan.Q: How do users benefit from the manual analog operation?

A: Manual, analog operation ensures direct, real-time readings without dependency on power sources or digital systems. This enhances portability, reliability, and ease of use in diverse environments.Q: What accessories are included with the viscometer?

A: Each unit comes with a leveling base for stable setup, a calibration certificate for quality assurance, and a comprehensive operation manual to guide users through setup, measurement, and maintenance procedures.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese Get A Quote

Get A Quote