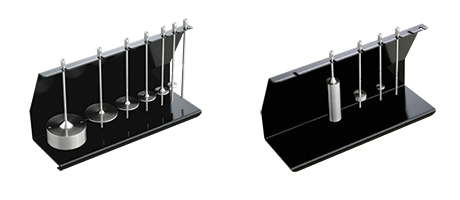

Standard Spindles

5000 INR

Product Details:

- Core Components Precision spindle shaft, calibration collar, threaded connector

- Feature Corrosion-resistant, easy-to-clean, high accuracy

- Temperature Range Ambient (20C25C) operating range

- Model No Standard Spindle Series (L1L4, R2R7, etc.)

- Capacity Variable, depends on model (standard laboratory spindle sizes)

- Measurement Range Model-dependent, suitable for broad range of viscosities

- Accuracy 1% (application dependent, based on viscometer calibration)

- Click to view more

X

Standard Spindles Price And Quantity

- 1 Piece

- 5000 INR

- Paints, inks, adhesives, creams, resins, food products, and more

- Screw-on or quick-connect (depending on viscometer)

- Factory calibrated with traceable certification

- Autoclavable and chemical sterilization compatible

- Polished, smooth for optimal fluid interaction

- Laser marked or engraved for easy recognition

- Compatible with Brookfield, Lamy, Fungilab, and other rotational viscometers

- Available for order volumes

- Cylindrical, plate, or cone geometry (model specific)

Standard Spindles Product Specifications

- Corrosion-resistant, easy-to-clean, high accuracy

- Precision spindle shaft, calibration collar, threaded connector

- Typically 100200 mm length, model-specific diameter

- Analog

- Variable, depends on model (standard laboratory spindle sizes)

- Standard Spindle Series (L1L4, R2R7, etc.)

- Ambient (20C25C) operating range

- Model-dependent, suitable for broad range of viscosities

- Approx. 50200 g per spindle (model-specific)

- Standard Spindle

- 50/60 Hz

- High-grade stainless steel (SUS 304/316) and precision engineered alloy

- Viscosity measurement with rotational viscometers

- Manual/Mechanical (no electrical input required for the spindle itself)

- Manual

- 1% (application dependent, based on viscometer calibration)

- Paints, inks, adhesives, creams, resins, food products, and more

- Screw-on or quick-connect (depending on viscometer)

- Factory calibrated with traceable certification

- Autoclavable and chemical sterilization compatible

- Polished, smooth for optimal fluid interaction

- Laser marked or engraved for easy recognition

- Compatible with Brookfield, Lamy, Fungilab, and other rotational viscometers

- Available for order volumes

- Cylindrical, plate, or cone geometry (model specific)

Standard Spindles Trade Information

- 5-10 Piece piece Per Month

- 6-8 Week

Product Description

Features

MEASURING SYSTEM: MS-ASTM / ISO 2555

Stainless steel discs measuring system for relative viscosity measurements in a 600-ml beaker. This system is used for measurements in accordance with the ASTM-ISO 2555 standard.

Viscosity range based on standard L speeds 3-60rpm and R/H speeds 5-100rpm.

| Reference | Viscosity range cP (mPas) | |

|---|---|---|

| | L1 V12401N | 15 20.000 |

| | L2 V12402N | 50 100.000 |

| | L3 V12403N | 200 400.000 |

| | L4 V12404N | 1.000 400.000 |

| | R1 V12501N | In R Models: 100 20.000 In H Models: 800 160.000 |

| | R2 V12502N | In R Models: 100 80.000 In H Models: 800 640.000 |

| | R3 V12503N | In R Models: 100 200.000 In H Models: 800 1.600.000 |

| | R4 V12504N | In R Models: 200 400.000 In H Models: 1.600 3.200.000 |

| | R5 V12505N | In R Models: 400 800.000 In H Models: 3.200.000 6.400.000 |

| | R6 V12506N | In R Models: 1.000 2.000.000 In H Models: 8.000.000 16.000.000 |

| | R7 V12507N | In R Models: 4.000 8.000.000 In H Models: 32.000.000 64.000.000 |

Designed for Precision Compatibility

Our Standard Spindles offer seamless integration with popular rotational viscometers like Brookfield, Lamy, and Fungilab. Model-specific mountingscrew-on or quick-connectfacilitates effortless installation and removal, allowing for consistent, accurate viscosity measurements every time.

Engineered for Versatility and Reliability

Built from premium stainless steel and precision alloys, these spindles are corrosion-resistant and smooth-finished for optimal fluid interaction. Their robust design meets the needs of painters, ink formulators, adhesive manufacturers, and food technologists seeking accurate, dependable viscosity data.

Traceable Calibration and Easy Identification

Each spindle comes factory calibrated with traceable certification, ensuring accuracy. Laser marking or engraving simplifies recognition, reduces errors, and streamlines laboratory workflow. Autoclavable construction supports stringent sterilization and hygiene requirements in critical industries.

FAQs of Standard Spindles:

Q: How do I select the appropriate spindle geometry for my application?

A: The suitable spindle geometrycylindrical, plate, or conedepends on your samples viscosity and the chosen viscometer model. Refer to your viscometers manual or contact our technical support for expert guidance on choosing the precise spindle for paints, creams, adhesives, or food products.Q: What is the process for calibrating these spindles, and do they come pre-calibrated?

A: All Standard Spindles are factory calibrated with traceable certification. No additional calibration is required upon delivery, but recalibration can be arranged if necessary, following standard viscometer procedures recommended by the manufacturer.Q: When should spindles be sterilized, and what methods are compatible?

A: Sterilization is recommended before and after handling sensitive samples, especially in food or pharmaceutical labs. These spindles are compatible with both autoclaving and chemical sterilization methods to ensure hygiene and prevent cross-contamination.Q: Where can Standard Spindles be used and with which viscometers?

A: Our spindles are versatile and can be used in laboratories or production environments where viscosity measurement is crucial. They are compatible with Brookfield, Lamy, Fungilab, and most standard rotational viscometer platforms in India and globally.Q: What are the main benefits of using polished, corrosion-resistant spindles?

A: Polished surfaces enhance fluid interaction for repeatable, accurate measurements, while corrosion-resistant materials guarantee durability, easy cleaning, and consistent performance over years of rigorous use. This combination ensures high sample integrity and minimal maintenance.Q: How can I order custom or OEM spindles for large-scale applications?

A: OEM customization is available for bulk orders. Contact our sales team with your specific requirementsincluding geometry, size, or brandingand well provide tailored solutions to fit your viscometer models and production needs.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Get A Quote

Get A Quote